In a pressroom, various processes take place to produce printed materials such as brochures, posters, packaging or magazines. Printing presses print thousands of copies in a short amount of time to meet tight deadlines. As a commercial pressroom operations manager, you’re responsible for overseeing your pressroom operations, ensuring equipment maintenance and checking the quality of all printed materials. You may also be responsible for workplace safety and finding ways to minimize job injuries.

With pressroom printing equipment, cutting and folding at high speeds, implementing pressroom safety measures is essential. The pressroom requires skilled operators who understand how to safely maintain a printing business’s efficiency, productivity and profitability. Learn about the common hazards and how to manage and reduce pressroom risks to create a safe workspace for your team.

With high demands often placed on the printing industry, it’s easy for occupational safety to be low on the priority list. However, safety plays a major role, and pressrooms must adhere to safety regulations from the Occupational Safety and Health Administration (OSHA).

Pressrooms can pose several occupational health and safety risks due to the nature of the equipment and operations involved. Employees are often unaware of all potential hazards in their working environment and can be more vulnerable to accidents or injury. In this context, safety refers to the measures and practices in place to protect everyone from harm while they go about their workday.

Safety is essential in the pressroom — it’s good for your business and employees. Safety has many other benefits, including:

Businesses should develop and review their safety policy annually — no matter their industry — and include the employer’s commitment to health and safety protocols at their organization. OSHA identifies several common types of hazards in most workplaces:

OSHA also requires all organizations to assess their workplace to determine the type of PPE their staff may require to protect themselves, no matter the size of the facility. People working in the pressroom may need PPE to prevent injury from moving around and operating printing equipment.

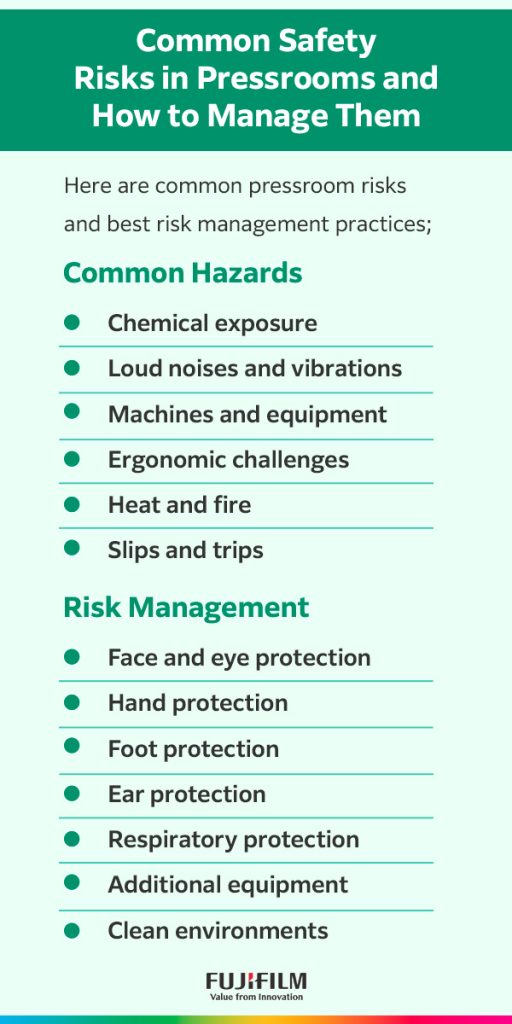

Employers should identify common hazards, inspect and maintain equipment regularly, and implement comprehensive safety protocols to ensure a safe pressroom environment. Employees should also receive appropriate PPE and regular training on pressroom safety. Here are common pressroom risks, best risk management practices, and the required general occupational health and safety training.

Pressroom managers can collaborate with their employees in hazard identification to record any potential risks in the pressroom. Identify potential risks when you add new processes or equipment to the standard workflow, during inspections and after an incident. Ideally, you should also look for hazards before each shift and during the work day.

These are general health hazards that can be found in the printing industry:

The ideal scenario is to remove all hazards. However, not all risks can be eliminated, especially when they form part of the necessary processes in the pressroom. In these cases, provide PPE and control hazards as much as practically possible.

Include the following items and actions to manage and reduce risk in the pressroom:

Identifying and minimizing hazards starts with knowledge and education. Pressroom managers can make improvements by training and educating their employees, ensuring they have better facilities and work environments, reviewing safety measures, and updating policies and procedures.

Train your staff by educating them on the following:

When prioritizing safety in any business, leaders must set an example for their teams to follow. They should implement safety policies and empower their staff to create a safety-first culture.

Everyone carries the responsibility to promote safety in and around the pressroom. However, it’s up to those in leadership positions to emphasize safety so the whole team is aware and can keep it in mind. Leaders should build safety awareness and policies in every aspect of their business. Some ideas you can implement to promote safety include:

While it is up to management to identify and control pressroom hazards to provide a safe and healthy work environment, employees must also remain aware of any risks and know how to prevent them. Employees should bring safety ideas and concerns to management’s attention as they become aware of hazards during their work every day.

Workers can feel empowered about their health and safety by:

If you’re a pressroom manager, your employees need easy access to occupational health and safety resources and support, whether the information is available on posters and signs, in company policies, or online. An online platform is a simple yet effective option for communicating all safety practices, record-keeping, risk assessments and training policies.

Here are a few options for leveraging online safety resources and support:

Pressrooms must train employees on all the potential hazards in the workplace. Always follow the instructions on safety data sheets for any inks and chemicals, and keep them in a designated area of the pressroom. Signs and markings help workers know where to walk safely and which areas are designated for other uses only, such as forklifts. Ensure everyone wears appropriate protective gear to minimize the risk of injuries.

Fujifilm Graphic Communication aims to enhance customers’ quality of life by creating high-quality products and services that are safe and secure. We pursue safety through the entire life cycle of all our products. Get in touch today to learn more about our printing products and solutions. We’re happy to answer any questions!